Developing a seed train for upstream bioprocessing involves optimizing many conditions – the medium, the feed, the starting inoculum density, etc. Integrating high cell density cryopreservation (HCDC) in the seed train also means considering parameters like the choice of cryoprotectant and freezing technique.

In HCDC, cells are frozen at high cell density and at larger volumes compared to the traditional expansion process. The ultimate goal in using HCDC is to intensify the upstream process to improve efficiency and productivity, reduce time, and contamination risks (see other benefits of HCDC here). Glutaraldehyde

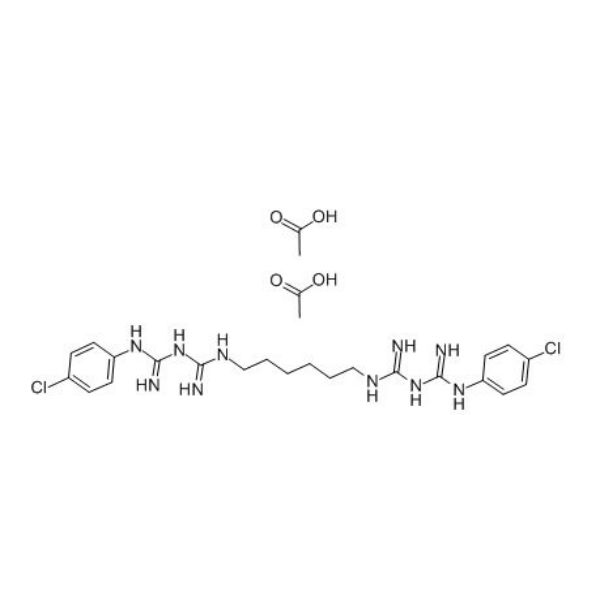

Here, we evaluated how dimethyl sulfoxide and freezing techniques impact viable cell density and titer production in an HCDC intensified seed train. While the HCDC process should be customized based on the cell line being used, the following offers a foundation for developing cell line-specific conditions.

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.

Please enter your email address and create a password to access the full content, Or log in to your account to continue.

Thymol Oil Please tell us more about you so that we can customize our newsletters to your specific interests: